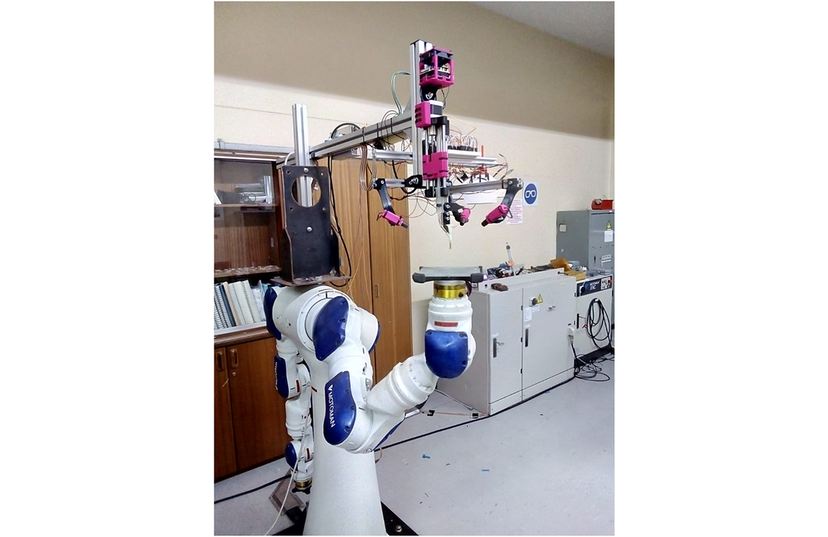

The DiCoMi project has inspired an exciting student research project at Stellenbosch University in South Africa. When Professor Andre van der Merwe watched Ian Campbell’s keynote presentation on the DiCoMI project at the 2019 RAPDASA international conference, it immediately got him thinking about different ways of achieving truly 3D additive manufacturing. His idea was to use a 6 degrees-of-freedom robotic arm coupled with a stationary photopolymer extruder to achieve 3D extrusion beads. Prof van der Merwe recruited student Daniel Kirkman to undertake the project, firstly as a Masters project and latterly as a PhD project. Daniel was able to realise the concept within the Department of Industrial Engineering research laboratory at Stellenbosch University. The overall system set up is shown in the image below

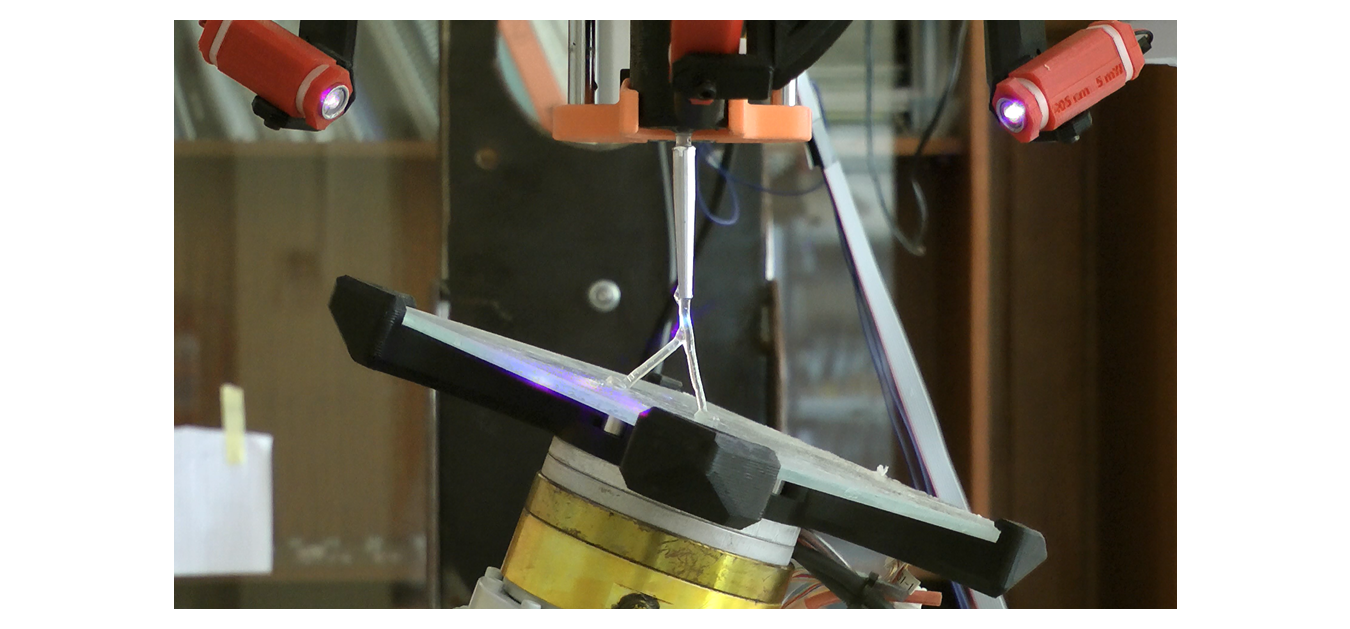

The system works by extruding a liquid photopolymer at a controlled rate though the extruder’s nozzle. The polymer is deposited onto a platform that can be simultaneously translated and rotated by the robotic arm. The material is quickly solidified by a series of UV light sources to create the 3D extrusion beads. A close-up of the extrusion process is shown in the following image.

The next stage in the project is to introduce reinforcement fibres into the extruded beads to improve both stiffness and strength. Early results look very promising with fibre volume fractions of 25% being achieved together with marked improvement in stiffness values.

The work has already led to the following two journal publications and more are expected to follow:

The work has already led to the following two journal publications and more are expected to follow:

- Kirkman, D. M., van der Merwe, A. F. and Campbell, R. I. (2019) ‘Development of a method of additive manufacturing by material extrusion along three-dimensional curves’, South African Journal of Industrial Engineering, 30(3), pp. 9–20. doi: 10.7166/30-3-2264.

- Kirkman, D., Van der Merwe, A. and Campbell, I. (2020) ‘System development for the five-axis extrusion of a photopolymer’, South African Journal of Industrial Engineering, 31(3), pp. 230–241.